Eco-friendly Products

Recycle Material

Recycling

Further advancements in eco-friendly technology

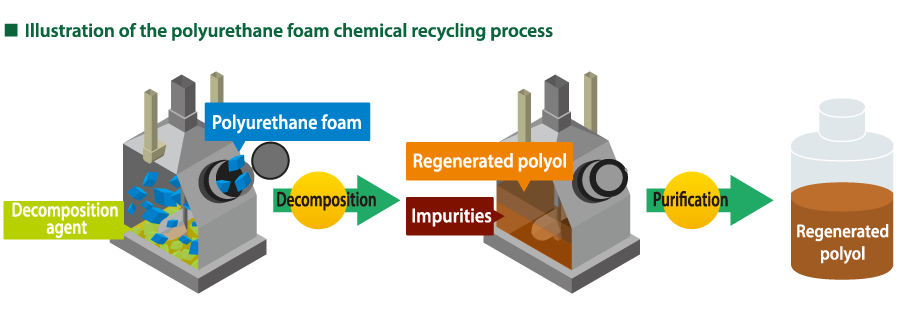

Polyurethane Foam

Chemical Recycling

Our main product at INOAC is polyurethane foam. Since it is foam material, much of its production is volume-based, and it is a resin that strongly needs to be recycled.

However, while some polyurethane foam waste is reused as materials and thermally recycled to be used as recycled materials and heat sources, some is also discarded without any efficient use. For that reason, we are working to boost its recycling rate by developing chemical recycling technologies to recycle the foam as raw materials.

Recycling

Efforts to significantly reduce waste

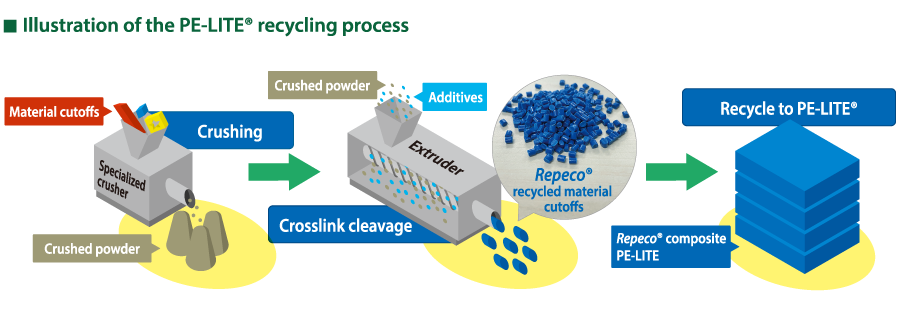

REPECO®

REPECO® is a pellet made by recycling cross-linked polyethylene foam (hereinafter referred to as PE Light®) cutoffs produced by INOAC.

Thanks to this recycling technology, nearly all material cutoffs can now be recycled into the original product they were produced for, PE-LITE®. We expect this to significantly reduce waste and improve usage efficiency.

Global environmental problems have reached critical stages in recent years, and carbon neutrality has emerged as a rallying cry. As an INOAC initiative, we are now using the material cutoffs recycled through this technology as part of the raw materials used when

producing PE-LITE®. This has reduced the usage of new material, ultimately reducing CO2 emissions and contributing toward carbon neutrality.

Recycling

Usage cycles to reduce our environmental footprint

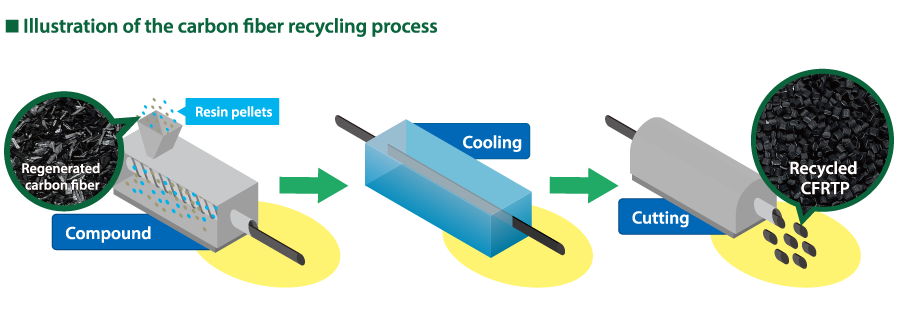

Carbon Fiber Recycling

Conventionally, carbon fiber reinforced plastic (CFRP) materials are high-performance high-priced composite materials that combine resins with carbon fibers made from petroleum and coal. Here, we reused high-value carbon fibers extracted from discarded CFRP products and combined them with thermoplastic resin to develop recycled carbon fiber reinforced thermoplastics (CFRTP). Since these high-performance resin materials offer the superior lightweight, high-strength properties of carbon fibers and can be processed and molded like normal plastics, they have great potential for use in a wide variety of products.

Consumer Products

Biomass Raw Material

Plant-Based Polyurethane Foam

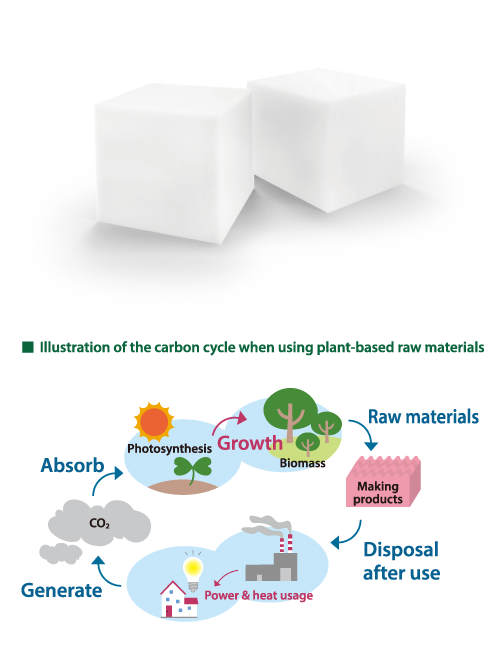

ECOLOCEL

ECOLOCEL is a flexible polyurethane foam made from at least 50% plant-based raw materials. This product offers two main advantages.

(1) Carbon neutrality that reduces dioxide (CO2) emissions

Carbon neutrality here refers to the approach of producing zero net CO2 emissions through the use of plant-based raw materials, balancing out the CO2 emitted when products are manufactured and discarded with the CO2 absorbed in the growth process of the plants resulting in no increases to CO2 released in the air over the life cycle as a whole. We developed ECOLOCEL based on this approach.

(2) Reducing dependence on fossil resources

We have chosen a method that keeps the earth's limited fossil resources form being exhausted and has no impact of food problems due to the use of non-food plant-based raw materials.

This foam is currently in use for making kitchen sponges, but we will be adding features such as high impact resilience, low resilience, and high hardness and deploying it for other usage applications such as mattresses in the future.

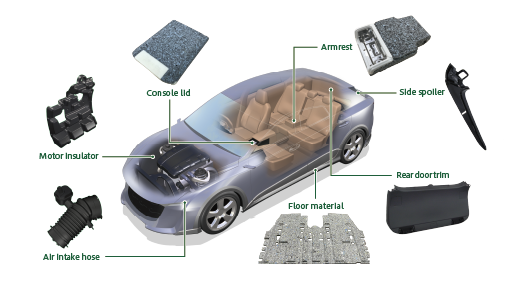

Automotive related products

Our environmental efforts in the automotive industry

It is said that the next few years will be a period of once-a-century change in the world of automobiles.

The inevitability of actions to realize carbon-neutral societies around the world has been suggested as one of the factors behind this.

Automobile OEMs are promoting the electrification of vehicles, and have launched proactive efforts to reduce CO2 across the entire supply chain, using LCA* as a basis.

INOAC is offering proposals for materials and components that can fulfill new needs created by the electrification of cars, as well as all sorts of suggestions that can reduce product CO2 without compromising product performance.

This page introduces some of the products we have commercialized.

*LCA = Life Cycle Assessment. This refers to a method of assessing the effect a product or service has on the environment through its life cycle, from procurement of raw materials to disposal.

Excellent designability

Compatibility with CO2 emission regulations

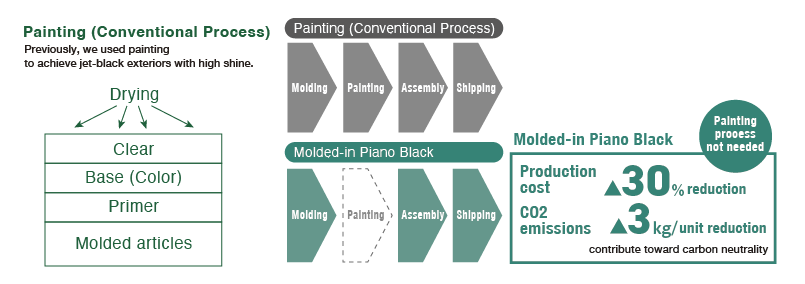

Molded-in Piano Black

■Effect

Reducing CO2 by stopping painting processes

■Summary

Using acrylic resin materials and polishing the die to a mirror shine means that we can achieve jet-black exteriors with high shine even without painting, creating a high-class feel.

We select steel materials with high hardness instead of general steel materials and maintain high temperatures in the die; together, these steps work as a clever technique that creates an attractive mirror surface.

Lightweight

Compatibility with CO2 emission regulations

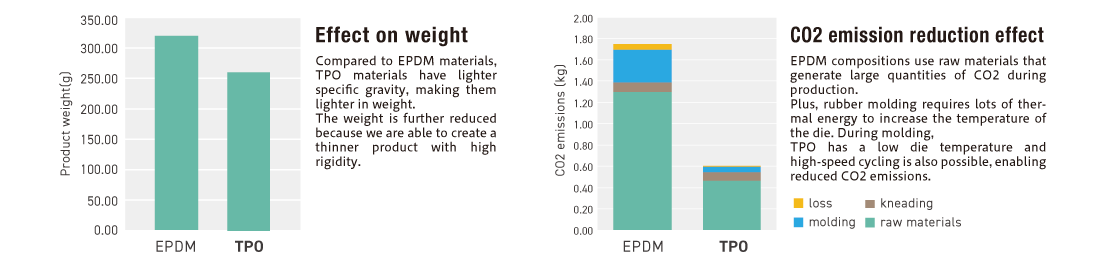

Making resin air intake hoses

■Effect

Materials recycle・Lightweight・CO2 emission restrictions

■Summary

Vulcanized rubber (e.g. EPDM) is the mainstream material used for engine air intake ducts, but we are switching to *thermoplastic olefinic elastomer (TPO).

We have developed environmentally friendly resin air intake hoses without compromising the product's performance.

*What is an air intake hose?

An air intake hose is a tube that takes in air, used as a part that connects the air cleaner and engine in the air intake system, which sends fresh air from outside the vehicle to the engine.

*Thermoplastic polyolefin elastomer (TPO)

A material produced by physically mixing a polymer with plasticity and a polymer with elasticity. The material can be used for regular injection molding and is also recyclable.

Recycle

Scrap material management and use

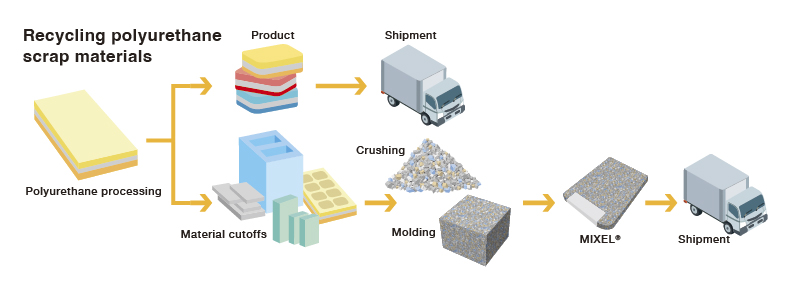

MIXEL®

■Effect

Product creation using managed scrap materials

■Summary

These products are created by crushing polyurethane scrap materials and mixing them with adhesives. We can create complex 3D shapes through molding.

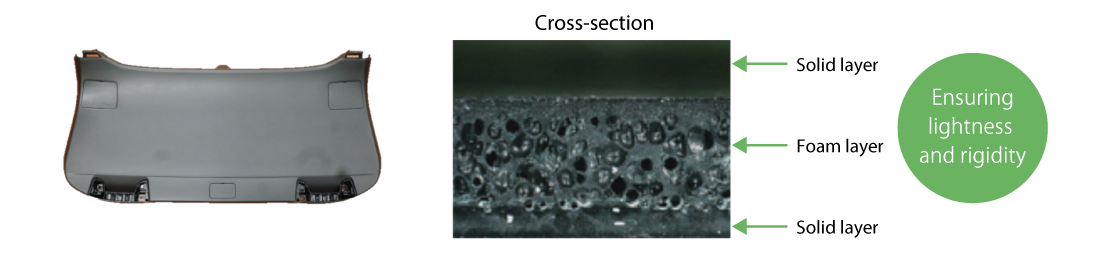

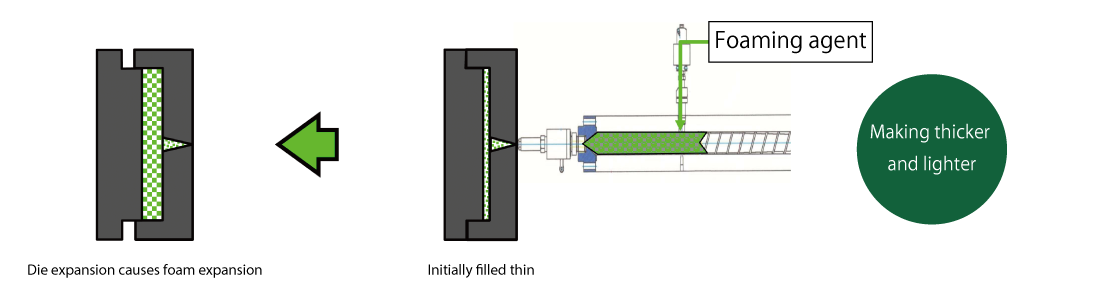

Lightweight

Compatibility with CO2 emission regulations

"Rear door trim" made lighter with large-scale injection molds

■Effect

Achieving both lightness and rigidity with large-scale injection molding technologies

■Summary

After the foamed resin is injected, the core back process* is applied to the die to expand the gas inside. This causes the foam to line the surface of the die, making it thicker and lighter.

This makes it possible to create a structure comprised of solid surface layers and a foam layer (in the middle). It furthermore increases the thickness of the plate, thereby ensuring lightness and rigidity.

*Core back

A method used during foam injection molding, where the volume of the die cavity is increased to expand the foam bubbles and create a high magnification foam-molded article.

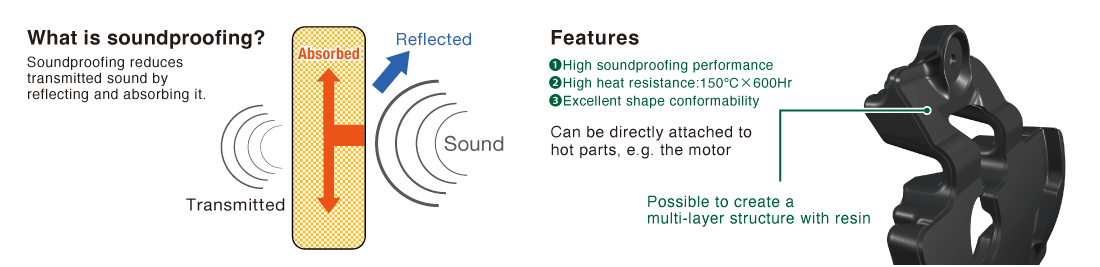

Sound absorption and insulation

Improving comfort

Motor insulator

■Effect

Noise reduction

■Summary

As vehicles are being electrified, the noise generated by units such as drive motors has become apparent.

We have made use of the sound absorbency and soundproofing performance of foam polyurethane to develop a material that offers high heat resistance and high shape conformability and make this into a product.

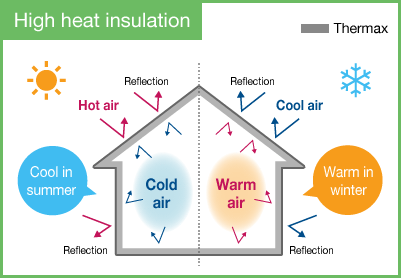

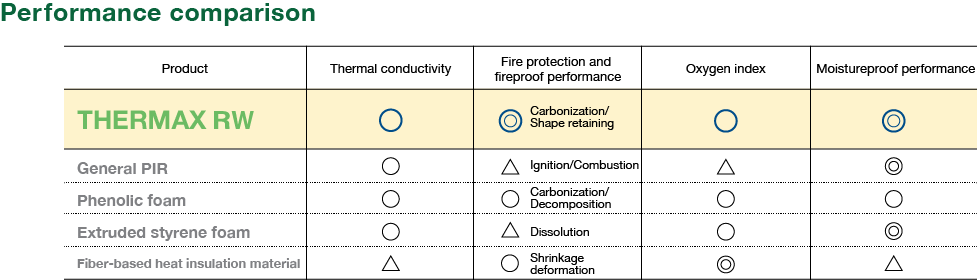

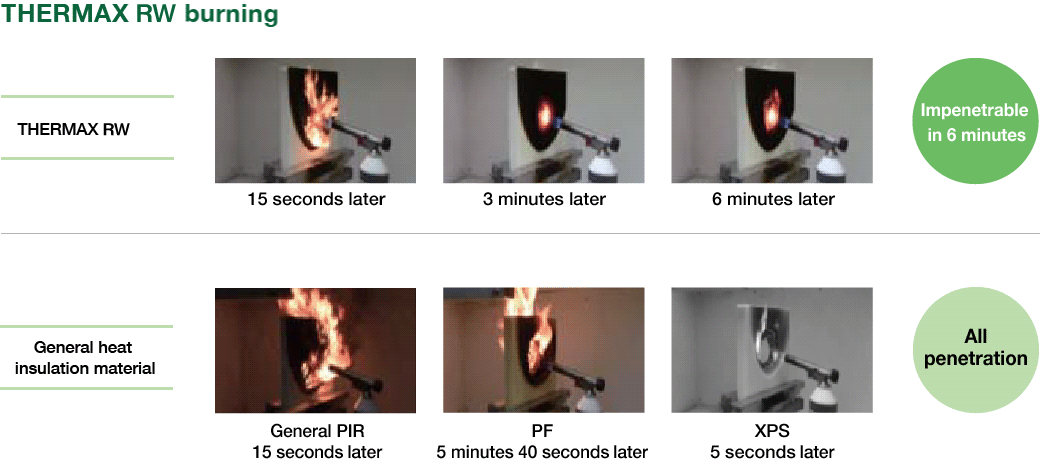

Building & Construction related products

Energy saving

Building heat insulator that can achieve both heat insulation and incombustibility

THERMAX RW

Recently, the demand for heat insulation materials has increased because of increasing interest in energy saving at residences; the demand for heat insulators for buildings that can achieve both heat insulation and incombustibility has also increased due to frequent large-scale fires. We developed THERMAX RW to respond to this demand. THERMAX RW is a rigid polyisocyanurate (PIR) foam board that prevents fire from entering inside due to a surface char layer formed by the isocyanurate structure; THERMAX RW has extremely high incombustibility even when burning on a burner at the temperature of 1200°C for 5 minutes as well as excellent thermal insulation performance.

Clean

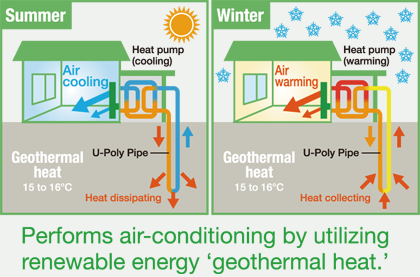

Developed version of 'U-Poly Pipe' that utilizes natural energy

Spiral heat exchanger for geothermal heat

Heat Exchange Equipment That Utilizes Geothermal System is a system that performs air conditioning and snow melting by utilizing stable heat (approximately 15 centi degree) 10 m to 100 m underground. "U-Poly Pipe" is a system used for air conditioning by exchanging liquid in the pipes installed underground with geothermal heat. The system utilizes natural energy, and thereby achieves low-consumption power.

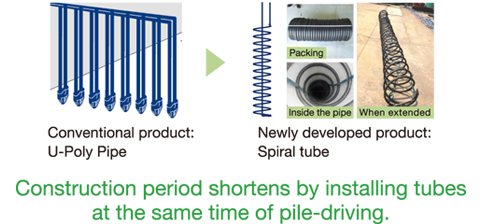

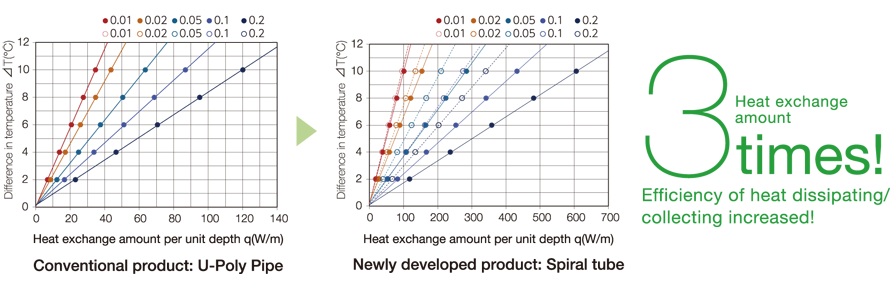

Buried Work Condition

Further, the "Spiral Heat Exchange Equipment" which was developed based on the "U-Poly Pipe" shortens construction periods and reduces cost through the installation of spiral underground tubes when pile-driving, a part of foundation work, is done. The amount of heat exchange per depth unit of spiral tube is approximately three times greater than when using conventional U-Poly Pipe. The efficiency of heat dissipation and collecting is drastically improved.

Comparison of Heat Exchange Performance

Comfort

Anti-vibration mat

CELLDAMPER

CELLDAMPER is a foamed polyurethane elastomer developed for use as an anti-vibration material to reduce oscillation. It provides excellent anti-vibration, and its production process includes no silicone or sulfur. It is a clean product with a low environmental load. Among other things, CELLDAMPER is an eco-friendly anti-vibration mat. Large-scale construction generates diverse types of oscillation that continue for a long period of time, which is likely to be an annoyance to others in the neighborhood. Accordingly, countermeasures against noise or vibration source should be taken at construction sites by improving heavy machinery and reducing noise, among other things. The CELLDAMPER mat effectively reduces oscillation just by spreading it out under iron plates at the site. It can reduce running vibration caused by heavy machine by 10 dB. This product is used as anti-vibration material on heliports, roof-top decks, and so on, as well as with equipment and automobiles that generate oscillation.

Benefits

- Vibration reduction due to an excellent damping effect

- Long-term performance due to low compressive set

- Clean material without silicone or sulfur

- Suitable to anywhere because of no rubber odor

- Cleared flame retardant regulations in each field.

Composite Materials

Energy saving

Composite with excellence in heat insulation, processability and flexibility

Flexible aerogel

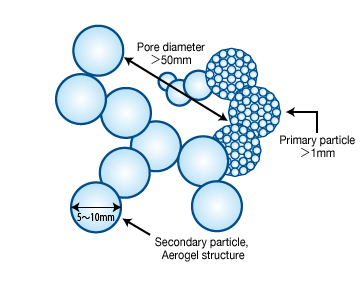

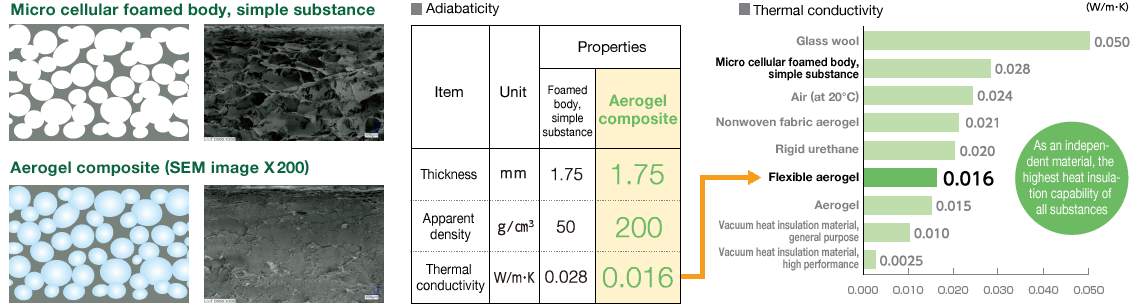

Aerogel is a dried porous gel with low density and high porosity, which is notably weak as a simple substance. Therefore, impregnating a nonwoven fabric base material with it or the like is required for commercialization, as a heat insulation material, due to weak points such as gel falling (powder falling) during use and insufficient heat insulation. Aerogel becomes an excellent product featuring extremely rare powder falling, high heat insulation, processability and flexibility by making a composite (filling in cell) with a special foamed body with a skin layer having a fine cell structure. Aerogel is expected to be utilized in various fields such as automobiles and construction materials in the future.

Clean

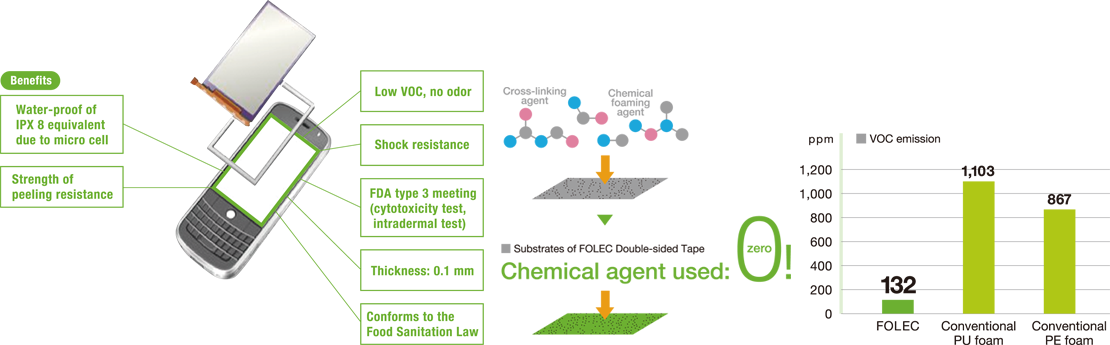

Eco-friendly with no chemical foaming agent used

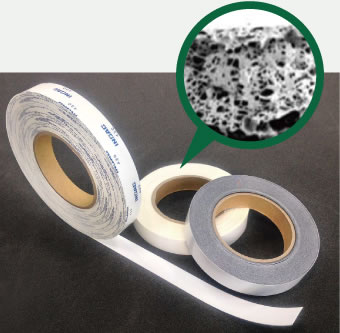

FOLEC Double-sided Tape

FOLEC is a micro-celled clean roll-sheet product manufactured by INOAC's original foaming technology without using a chemical foaming agent. FOLEC Double-sided Tape is produced using FOLEC as the base material, and therefore provides excellent dust-proofing, water-proofing, and shock absorption. It will lead to a reduction of the chemical substances used and never breed* chemicals even when used for a long period of time, because it does not contain a chemical foaming agent.

*Breed: phenomenon of chemical substances oozing out to the surface.