SEALFLEX Mold

- Transportation

- IT Equipment

- Housing & Construction

- Medical & Welfare

- Consumer Products

- Industrial Machinery

- Distribution & Packaging

- Electric Products

- Sound

- Vibration

- Shock

- Heat & Temperature

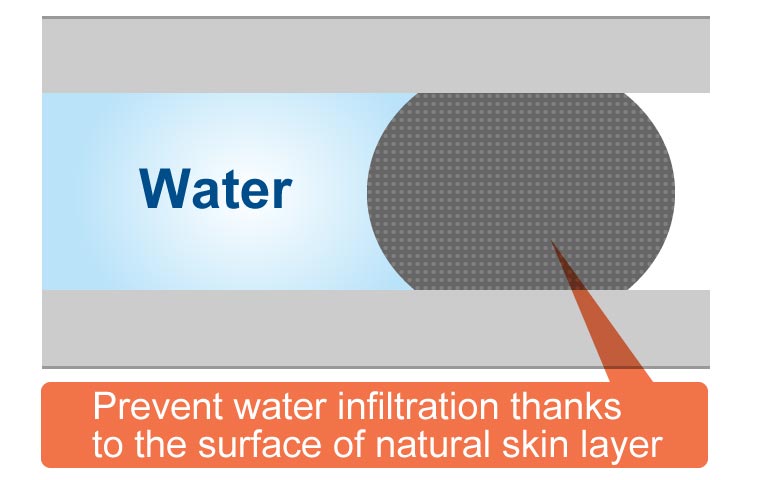

- Sealing

- Filtering

- Light Weight

- Comfort

- Low Combustibility

- Others

- Polyurethane

- Rubber

- Plastics

- Composites

About SEALFLEX Mold

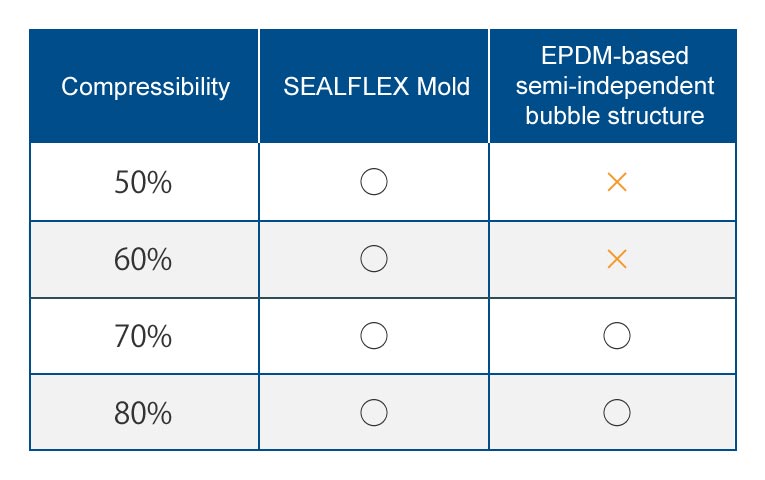

SEALFLEX Mold is a semi-open cell-type rubber sponge sealing part, which is made of INOAC's unique foaming technology. It has outstanding structure intensity such as tearing strength. It has also good cushioning and weather and chemical resistance. Due to these features, it can be used in many fields such as housing, civil engineering, automotive, electric goods, and so on.