INOAC & TOYOBO

Hybrid Futon mattress Secret development story interview

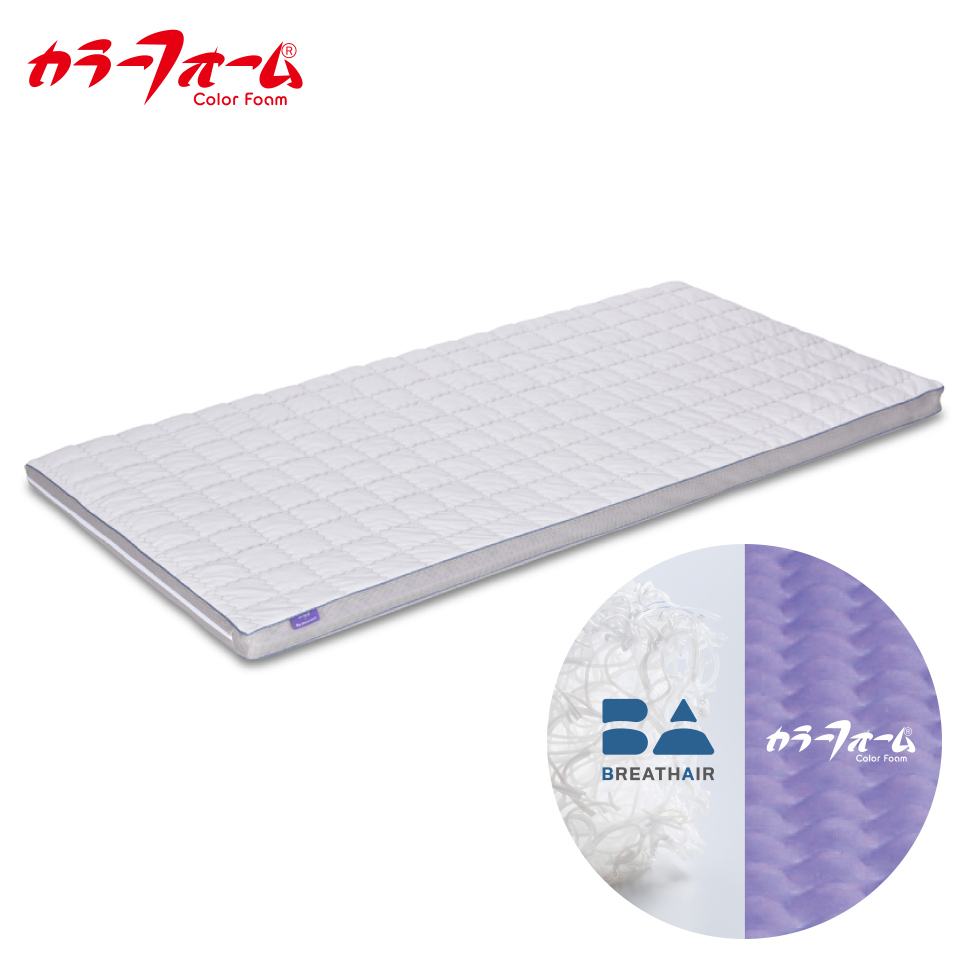

At the beginning of September 2017, INOAC LIVING CO., LTD. started selling the reversible Hybrid Futon mattress that offers comfort in summer and winter, which was developed in association with TOYOBO CO., LTD. What did this collaboration between two companies who could be rivals in the bedding industry mean? We had the persons in charge who were concerned with this plan at both companies look back on the path that was taken until the product was marketed.

This mattress, comfortable in all seasons, is produced thanks to the collaboration on materials having excellent compatibility with each other.

INOAC LIVING CO., LTD. Keisuke Saeda

| 1992 | Entered INOAC LIVING CO., LTD. Engaged in planning and development |

|---|---|

| 1996 | Sales division of INOAC LIVING CO., LTD. Nagoya |

| 2005 | INOAC LIVING CO., LTD. Tokyo Planned to launch Color Foam mattress |

| 2007 | INOAC Vietnam (IVC) |

| 2009 | Head of sales office of INOAC LIVING CO., LTD. Nagoya |

| 2016 | Development manager of INOAC LIVING |

| 2017 | Engaged in the collaborative development of the Hybrid Futon mattress |

TOYOBO CO., LTD. Mayu Fujimoto

| 2006 | Entered TOYO BOSEKI CO., LTD. (Current TOYOBO CO., LTD.) After training at the spinning mill of the Toyama office, assigned to the comprehensive research institute in Shiga |

|---|---|

| 2007 | Transferred to BREATHAIR group of HQ Engaged in sales of BREATHAIR® |

| 2017 | Engaged in collaborative development of the Hybrid Futon mattress |

Sudden encounter

FujimotoIt was the INOAC exhibition booth of the gift show held in February in 2017 where I met Mr. Saeda.

SaedaAt the beginning of 2017, an opportunity arose and the heads of INOAC and TOYOBO discussed developing a collaborative product. We worked to produce a bedding product using TOYOBO’s BREATHAIR® (hereinafter ® omitted) and INOAC LIVING’s polyurethane materials as the first product and we came to meet about this.

FujimotoI heard that this started with the president of INOAC saying he wanted some products made with other TOYOBO materials since he uses their automobile tires.

SaedaReally? I didn’t know that. Actually, INOAC started with automobile tires. Our current business can broadly be classified into rubber and plastic including automobile tires and the urethane business including INOAC LIVING’s major products.

FujimotoI went to greet Mr. Saeda with the sample of BREATHAIR. Then, he asked me many questions, even about the smallest details. For example, the difference between the hollow type and the solid type (Fiber types of the BREATHAIR- the one with a cross section looking like a macaroni is the hollow type.The hollow type is harder when compared in the same weight.) and everything. I felt happy like “Ah, he knows what craftsmanship is and he loves that.”

“This is great!”

SaedaI already knew about TOYOBO’s BREATHAIR. But I found that I didn’t know the details when the collaboration started. I asked many things, including the characteristics, densities and prices of thick and thin fibers. When I received samples, I thought that these were great materials.

FujimotoI repeatedly traveled between Osaka where I work and Tokyo to attend many meetings; finally the prototype was completed in April.

SaedaThat was definitely a crash program. I lay down on many mattresses in different combinations of our polyurethane and the delivered BREATHAIR, with different densities of BREATHAIR, and with different hardness of polyurethane and everything, over and over.

Normally, it is very difficult to complete a product in such a short time. Fortunately, both materials fitted each other.

FujimotoOn May 31, we invited the president of INOAC to our research institute in Shiga to show him the prototype. Our managing director was with him and he said “This comfort and luxurious feel are unbelievable. This is great!” That was his highest praise.

SaedaBasically, the BREATHAIR is a high-elastic just like a spring. We put our polyurethane foam on this high-elastic material as an upper layer. At first, the polyurethane softly receives the body and the BREATHAIR supports the whole body like springs. That is the image. It is a major advantage that the BREATHAIR also offers excellent air permeability.

The craftsmanship utilizing the advantages of both materials bore fruit.

FujimotoWe struggled to complete the project, thinking and working on various combinations through trial-and-error. I was really happy when commercialization was determined at the prototype stage.

Mr. Saeda is very quick to understand about the BREATHAIR since he’s been handling urethane for a long time. You immediately understand what makes what so we didn’t have to waste time by making unnecessary samples.

SaedaI could understand easily because Ms. Fujimoto quickly responded to what we said. However, I felt pressure since the president then kept on asking me “When can we announce it?” every day in Tokyo. I was so relieved when we could announce it at the interior expo in July.

Experts use this in their personal life

SaedaThe Hybrid Futon mattress on sale is designed as a reversible mattress. The BREATHAIR side can be used in summer and the Color Foam side can be used in winter. Both the BREATHAIR and the Color Foam are available as internal materials. This collaboration results from further pursuit of sleep comfort by both INOAC LIVING and TOYOBO.

FujimotoIn fact, you can feel comfort from polyurethane. Very comfortable to lie on. To tell the truth, I’m using the Hybrid Futon mattress at home (laughs). I have used the BREATHAIR only. But the Hybrid Futon mattress is much more comfortable. Apart from the fact that I was involved, I now love the Color Foam (laughs).

SaedaActually, I’m also using the Hybrid Futon mattress. I used a spring mattress before…

FujimotoNot a polyurethan foam?

SaedaThat’s right. Not polyurethane. The Hybrid Futon mattress is softer than a spring mattress thanks to the polyurethane in the upper layer. It is also easy to move in bed because the BREATHAIR under the upper layer supports the body instead of springs. The excellent compatibility of both materials just surprised me.

FujimotoINOAC team was also particular about the details and selected a higher density type of BREATHAIR than we first thought of. It is well arranged to prevent the bottom from sticking to the floor.

SaedaA very firm density material is used for the upper layer of polyurethane. There are two types, 8 cm and 10 cm, for the Hybrid Futon mattress and they both have dedicated covers. They are different in the thickness of BREATHAIR, cover material and its thickness. We really recommend checking the difference in comfort between them at the showroom.

The new and comfortable Hybrid Futon mattress was born from a sudden meeting. It would be our great delight if we can help you to have a wonderful experience with this product.