About Product

Product Varieties

There are three types of carbon composite materials

- ①「RL-C」- Thermoset plastics Type(Heat Press Molding)*Material:Carbon+Foam

- ②「RL-CT」- Thermoplastic Type(Heat Press Molding)

- ③「RL-CP」- Thermoset plastics Type(Pultrusion Molding)

①「RL-C」- Thermoset plastics Type(Heat Press Molding)*Material:Carbon+Foam

Meaning of「RL-C」= Rigid Light®-Carbon

「RL」stands for “Rigid Light” that represents high rigidity but yet light weight products that INOAC can provide,「C」highlight the Carbon as main materials of this product.

Features of「RL-C」

Beside the「Light Weight」and 「Strong」that can be realized by combining Carbon and Foam, it also provides benefits of 「Easy to Molding」and「Cost Reduction」.

「Multiple thickness forming」can easily be done in molding process.

RL-C Rigidity Data

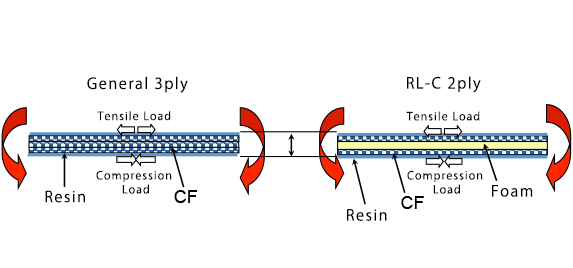

Bending Strength(JIS K-7074) t0.7[mm]thickness

- General CFRP 3ply: 69.4[GPa]

- INOAC RL-C 2ply: 62.4[GPa]

Surface layers (top and bottom) are made of CF fabric.

☆Middle layer is replaced by Foam ⇒Cost Reduction and Light

Weight.

Easily Molding

Process

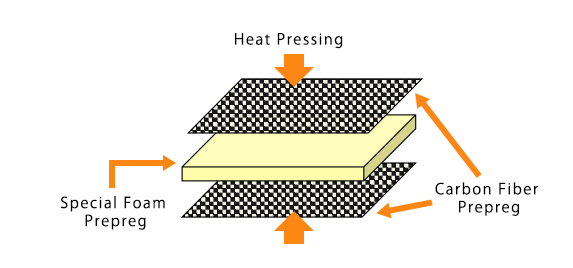

- Possible with「Heat Pressing」process

- Not necessary to use「Autoclave」and「Vacuum Forming」

Product design

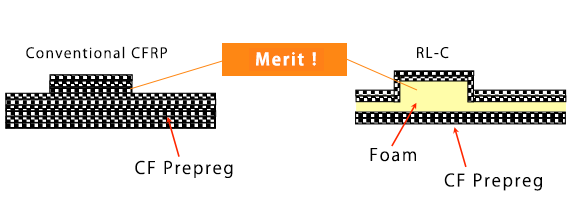

Foam layer absorbs uneven and thickness deviation parts, so multiple

thickness design is possible.

As a result, logo design and other parts fitting can be done on one side while maintain flat on the

other.

Cost Reduction

Structure

- Conventional CFRP must be laminated multiple expensive carbon prepregs to adjust thickness.

- Conventional CFRP must be prepared and laminated precise size of carbon prepregs to thicken partially.

- For「RL-C」the internal foam can be easily formed thus no need for multiple lamination and amount of carbon prepreg is also reduced and realize cost reduction.

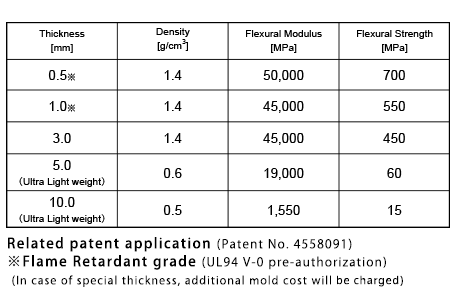

Property Information

Physical properties

Commercial data of「RL-C」

- ① Prepreg

The prepreg plate for thermosetting is available. - ② Plate

The thermoset plate is available. - ③ Product

The product shape depending on design is also available. - ④ Technical assistance

Depend on customer requirement, technical assistance for mold design, molding condition and other support including onsite support can be provided (Additional cost will be charged).

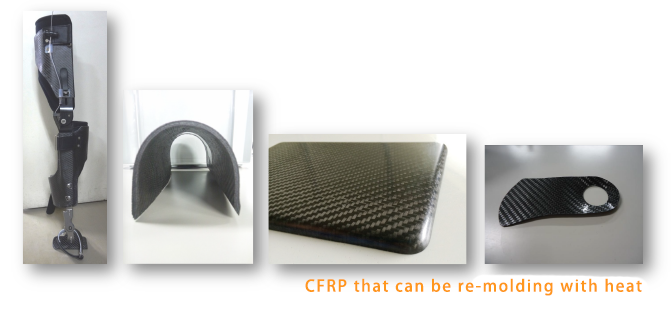

②「RL-CT」- Thermoplastic Type (Heat Press Molding)

CFRP that can be shaped with heat「RL-CT」

Rigid Light-Carbon Thermal=Thermoplastic Carbon Prepreg

Feature of「RL-CT」

The molding process of「RL-C」series new product「RL-CT」can be seen on YouTube.

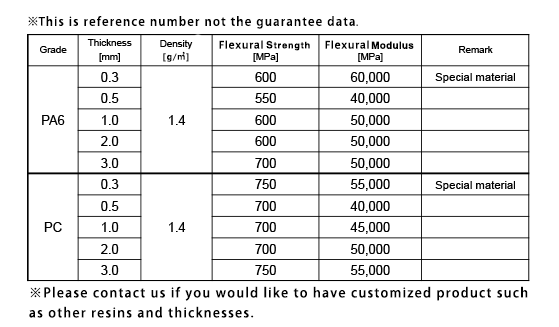

Physical properties

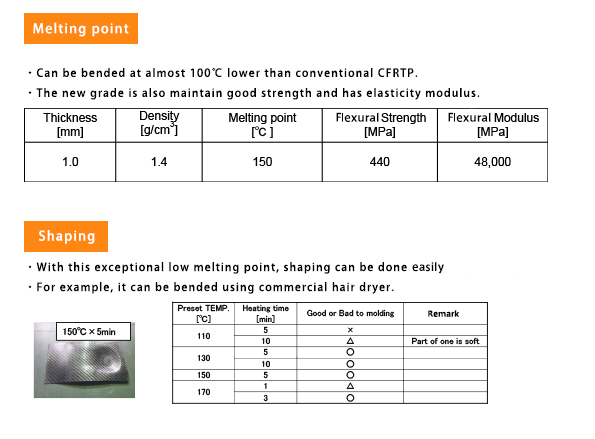

New Grade of「RL-CT」(Low melting point Model)

CFRPTP easy molding material that can be molded at the low temperature of 150℃

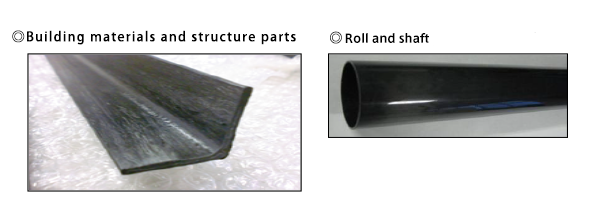

③「RL-CP」-Thermoset Type(Pultorusion Molding)

「RL-C」 series new product「RL-CP」

Rigid Light-Carbon Pultrusion =Pultrusion product

Features of「RL-CP」

The blending process between resin and glass / carbon fiber is simultaneously occurred during extrusion.

Sample Application

- Railways project parts - Snow melting equipment(GFRP)

- Solar panel - Support Stand(CFRP)